40 YEARS OF PRECISION

40 YEARS OF PRECISION

Automatic precision turning in the province of Treviso

From artisan turning to industrial production …

Our Structure

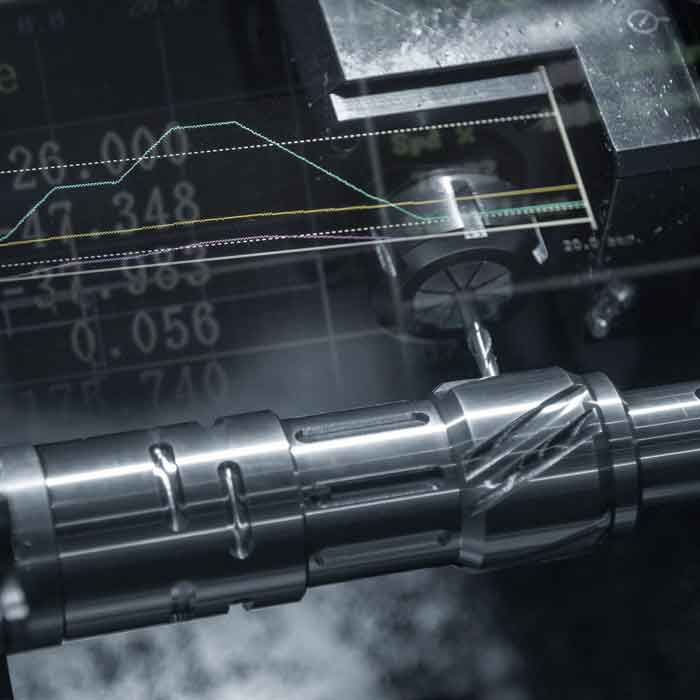

TAB stands at the foot of Monte Grappa, in the epicenter of the most productive area of Italy. The modern structure, developed in 3,000 meters of covered area, is organized in different departments: the design, equipped with cutting-edge software entrusted to specialized engineers; the raw materials warehouse, thanks to which TAB is able to reduce delivery times; the workshop has numerous latest generation CNC lathes, various machineries for the machining of mechanical components suitable to meet every customer need; assembly and quality control which, according to the strictest standards, checks every aspect of the finished product.

Our Means

TAB, an automatic precision turning shop in Borso del Grappa, is a cutting-edge company that makes research and anticipation of the market its strengths.

Quality Management

TAB anticipates the market, always in rapid and constant evolution, going beyond traditional means. The experience accumulated over the years has led the company to be able to “self-generate”. TAB, when needed, designs and builds new equipment capable of carrying out specific processes that meet the customer’s requests.

Guarantees

In the TAB philosophy, a production cycle ends with customer satisfaction. Every single order is handled with the utmost transparency, both in the technical and commercial aspects. The request is analyzed in depth and evaluated in different development possibilities. It follows a detailed wording, which makes the achievement of the expected result inevitable.

Online quote for express service

Product sectors

TAB always aims to offer, for the same product, the best price on the market. Any request for online quote on the service of precision small parts and products offered by the company are analyzed by the responsible staff, loaded on dedicated calculation software, the procurement times of raw materials, standard processing and any special interventions are estimated to offer the customer a express service.